Tiny Hairs, Gigantic Leaps: 3D-Printed Micro-Robots Promise Medical Revolution

Tiny Hairs, Gigantic Leaps: 3D-Printed Micro-Robots Promise Medical Revolution

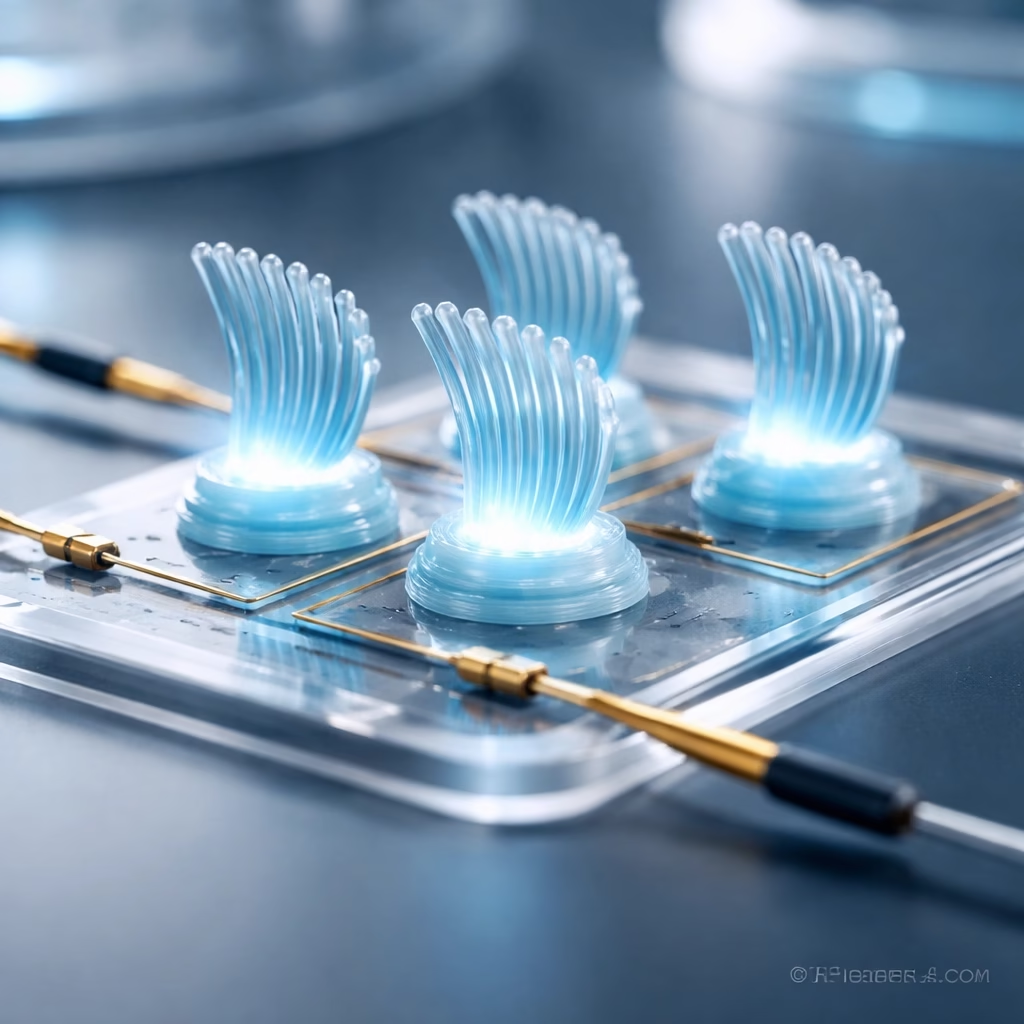

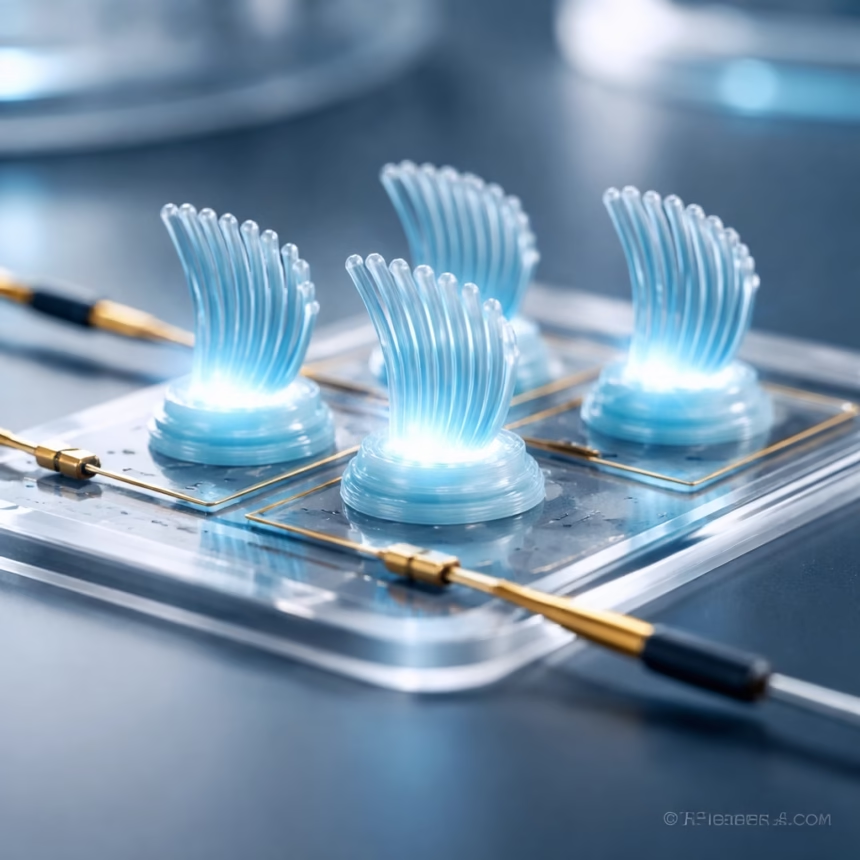

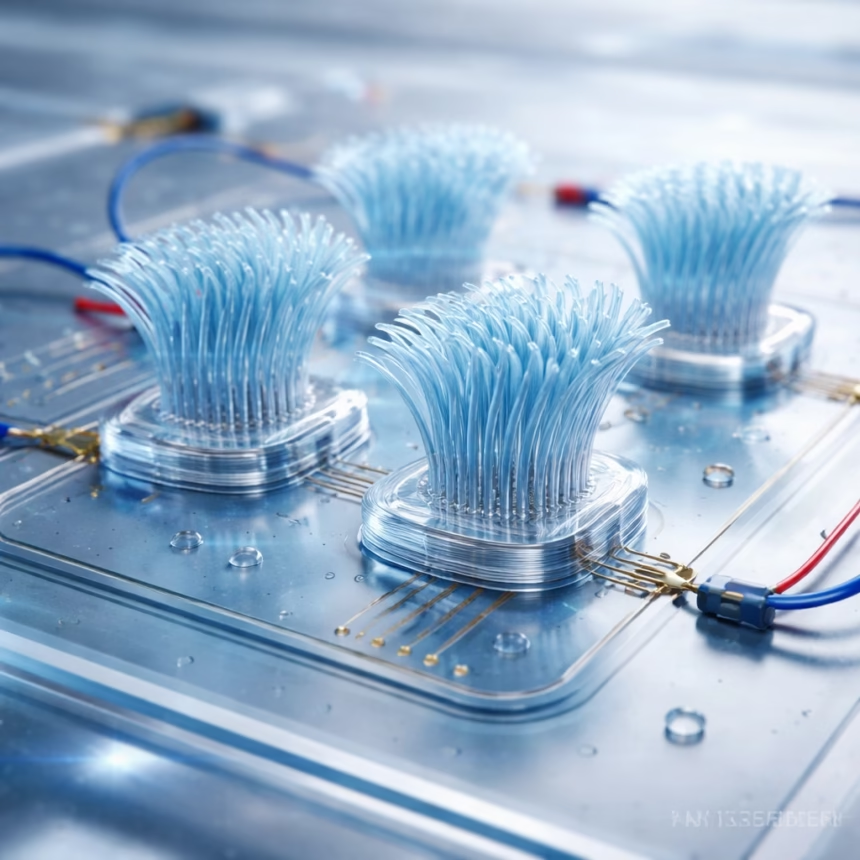

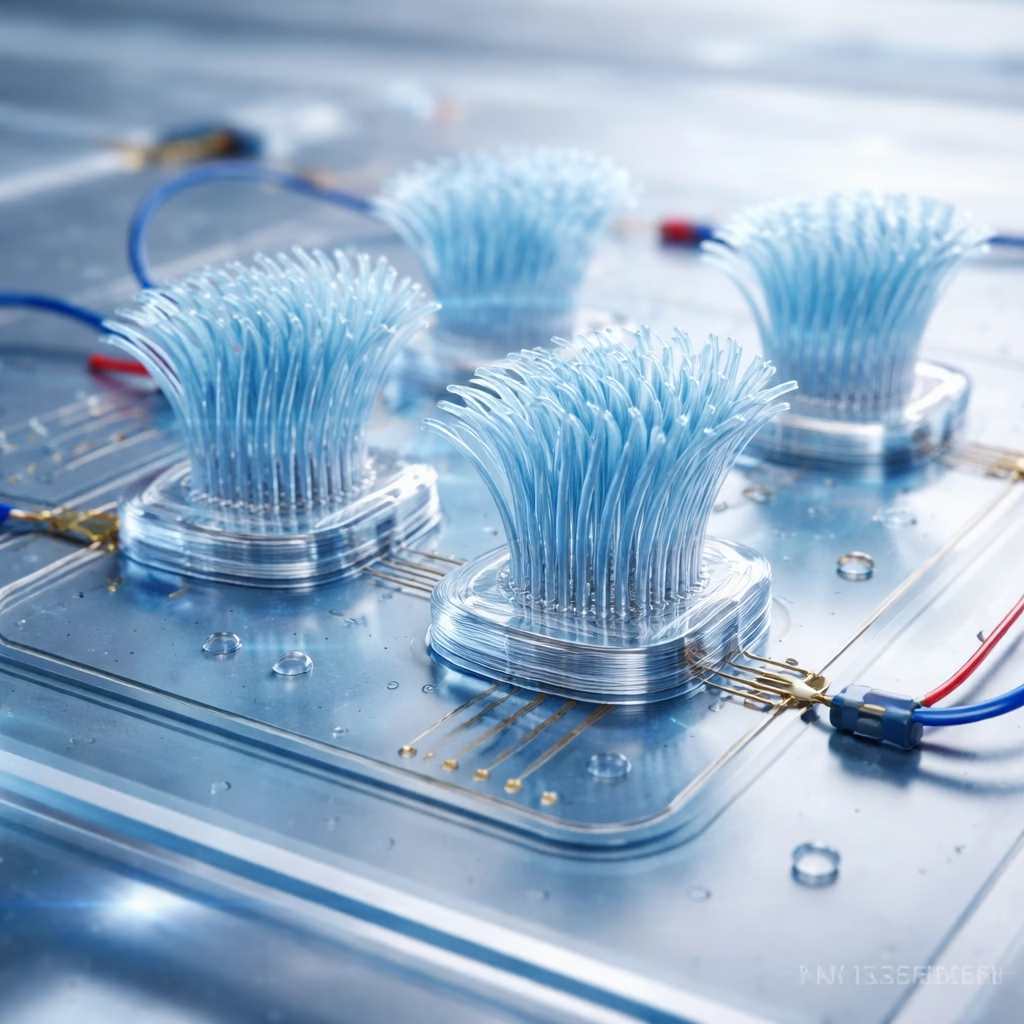

Scientists at the Quantum Dynamics Lab, a leading research institution in Europe, have unveiled a groundbreaking development: 3D-printed ciliary hydrogel microactuators. These microscopic, hair-like structures, driven by remarkably low voltages, promise to revolutionize fields from targeted drug delivery to advanced soft robotics. The breakthrough, detailed in a recent publication earlier this month, marks a significant step towards practical, bio-inspired micro-scale machinery.

Background: The Quest for Micro-Motion

The concept of micro-actuators, devices that convert energy into mechanical motion at the micro-scale, has captivated researchers for decades. These tiny machines hold immense potential for applications ranging from intricate surgical tools to advanced diagnostic systems. However, developing functional micro-robots has historically presented significant challenges.

Traditional micro-robotics often rely on complex, multi-step fabrication processes, rigid materials that limit flexibility, and power sources requiring high voltages or external magnetic fields. These limitations hinder their integration into delicate biological environments and restrict their autonomy.

The inspiration for the latest breakthrough comes from nature itself: biological cilia. These hair-like organelles found in many organisms, from single-celled protozoa to human respiratory tracts, perform vital functions like fluid transport and propulsion through coordinated, rhythmic beating. Mimicking this natural motion at the micro-scale has been a long-standing goal in engineering.

Hydrogels, soft, water-swollen polymer networks, emerged as a promising material due to their biocompatibility, flexibility, and responsiveness to various stimuli such as pH, temperature, and electric fields. Their ability to swell and contract in response to external cues makes them ideal candidates for soft robotics. However, precisely structuring these materials into complex, active micro-actuators has been a formidable hurdle.

The advent of advanced 3D printing (additive manufacturing) technologies has progressively opened new avenues. Early 3D printing methods lacked the resolution and material versatility needed for such intricate hydrogel structures. Over the past decade, however, significant advancements in micro-scale 3D printing have begun to bridge this gap, paving the way for the fabrication of increasingly complex and functional soft micro-devices.

Key Developments: Precision Printing and Low-Voltage Control

The core of this new research lies in a novel approach to 3D printing combined with a specially formulated hydrogel. Led by Dr. Elara Vance and Professor Kai Chen, the team at Quantum Dynamics Lab developed an advanced micro-stereolithography technique. This method allows for the direct printing of complex, three-dimensional hydrogel structures with unprecedented sub-micrometer resolution, making it possible to fabricate individual cilia with precise dimensions and orientations.

The breakthrough material is a custom-synthesized conductive hydrogel. This proprietary polymer network is engineered to respond rapidly and predictably to electrical stimuli. When a low voltage is applied across specific regions of the hydrogel, it induces localized ion movement and osmotic pressure changes within the material. This electrochemical reaction causes the hydrogel to swell or contract, resulting in rapid and controlled bending or beating motions.

Crucially, these ciliary microactuators operate on remarkably low voltages, typically ranging from 1 to 3 volts. This is significantly lower than many previous electro-active micro-systems, making them compatible with small, portable power sources, such as standard coin-cell batteries. The low power requirement reduces heat generation and enhances safety for potential biological applications.

The researchers demonstrated the ability to print arrays of these cilia in specific patterns, mimicking the coordinated beating seen in biological systems. By precisely controlling the applied voltage and its timing, they achieved rhythmic, synchronized, or even independent actuation of individual cilia or groups of cilia. This fine-tuned control enables complex fluid manipulation, such as directed pumping, efficient mixing of micro-scale solutions, and the controlled propulsion of micro-particles.

This development represents a significant leap from passive hydrogel structures to actively controllable, complex micro-machines. It overcomes previous challenges in fabricating intricate, responsive hydrogel devices, offering a new paradigm for micro-scale motion and interaction.

Impact: Revolutionizing Medicine and Micro-Engineering

The potential applications of these 3D-printed ciliary hydrogel microactuators span numerous fields, promising transformative impacts:

Healthcare and Targeted Therapies

Perhaps the most profound impact is anticipated in medicine. Imagine microscopic robots, equipped with these ciliary actuators, navigating the human bloodstream to deliver chemotherapy drugs directly to tumor cells, minimizing side effects on healthy tissues. They could also be used for highly precise, minimally invasive procedures, such as targeted biopsies or intricate surgeries within delicate organs like the eye or brain, reducing patient recovery times and risks.

In diagnostics, these micro-actuators could enhance “lab-on-a-chip” devices, improving the efficiency of fluid mixing and particle sorting, leading to faster and more accurate disease detection from minuscule blood or fluid samples.

Soft Robotics and Microfluidics

The development paves the way for a new generation of soft, compliant, and biocompatible robots. Unlike rigid conventional robots, these flexible micro-bots could safely interact with delicate biological tissues and navigate complex, confined environments. In microfluidics, the ability to precisely pump, mix, and sort fluids at the micro-scale will revolutionize laboratory research, chemical synthesis, and drug screening processes.

Environmental and Industrial Applications

Beyond biology, these micro-actuators could find uses in environmental monitoring, such as detecting pollutants in water samples or even aiding in micro-remediation efforts by manipulating contaminants. In industrial settings, they might be integrated into advanced micro-cooling systems or self-cleaning surfaces, leveraging their ability to manipulate fluids at a tiny scale.

The low power requirements and the scalability of 3D printing promise more affordable and accessible production, potentially democratizing access to advanced micro-robotic technologies.

What Next: Future Milestones and Challenges

While the current breakthrough is significant, researchers are already looking ahead to the next phase of development and application:

Enhanced Control and Integration

Future work will focus on developing more sophisticated control systems, potentially incorporating artificial intelligence and machine learning algorithms for autonomous navigation and complex task execution. A critical step will be the integration of these actuators with other micro-components, such as micro-sensors, cameras, and tiny drug reservoirs, to create fully functional, multi-tasking micro-robots.

Biocompatibility and *In Vivo* Testing

For medical applications, rigorous testing for long-term biocompatibility, stability, and controlled degradation within biological systems is paramount. The next major milestone will involve initial *in vivo* trials in animal models to assess the performance, safety, and efficacy of these micro-actuators for specific medical applications, such as targeted drug delivery to tumors or navigating vascular networks.

Scalability and Commercialization

Refining the 3D printing process for mass production and further cost reduction will be essential for widespread adoption. Researchers anticipate exploring partnerships with industry to translate this lab-based innovation into commercially viable products. For medical devices, navigating stringent regulatory approval pathways will be a significant and lengthy undertaking.

Dr. Vance and Professor Chen anticipate initial *in vivo* studies within the next three to five years, with human clinical trials potentially a decade away, underscoring the long-term vision for this groundbreaking technology. The journey from tiny hairs to gigantic leaps in medical science and beyond has only just begun.